Spring Boat Maintenance Tasks

Springtime is the best time to prepare your boat for prime boating season, but here are some things you may have missed or didn't think about when you winterized your boat.

Anodes

Anodes act as an underwater conduit for electrical shorts and are designed to disintegrate over time instead of crucial mechanical components. They provide an indication of what your other metal mechanical components would look like if they weren't there. If they're about half gone, replace them. Also be aware that you may need a different material depending on where you run/keep your boat.

- Saltwater: Aluminum anodes are more active, protect better, and last longer than zinc anodes in saltwater – a win/win situation.

- Brackish Water: Aluminum anodes provide superior protection here. ...

- Freshwater: Magnesium is the clear anode of choice.

(Fisheriessupply.com)

Note: If the anode is gone or super corroded, check all the other submerged metal parts to ensure they didn't also suffer from galvanic corrosion.

If you have an outboard or a sterndrive, you can buy a set, and the set should have exactly the right number to replace your anodes. Keep in mind, some of them may be hard to find/see. If you notice that your anode is disappearing before the end of the season, you may have more serious electrical problems with your boat. Run a search down all of your DC wires and battery cables and be on the lookout for chafed, frayed or bare wires. This kind of situation can be very dangerous and can cause a fire.

Note: Keep in mind that corrosion is not usually covered by insurance.

Watch Video: Replace Sterndrive Anodes

(Photo: www.boatus.com)

Props and Hull

Inspect props.

When looking over your propeller, keep an eye out for chipping, dents, pitting, warps, or anything that can potentially cause excessive vibration or cavitation. You can damage your drive train, transmission, or rattle screws, bolts, and your passengers loose. Check the bolts holding everything together including the cotter pins. It's not uncommon for tow assistance claims to call in because the prop fell off. A good machine shop/prop shop can usually repair bent props with minor damage. If you have an inboard-powered boat, grab the shaft and try to move it from side to side within the cutless bearing. If it's loose you will most likely need to replace the bearing.

While you're down there inspecting the prop, it's not a bad idea to check all the drain plugs. Make sure they are sealed and tight.

Watch Video: How to Replace a Propeller

Inspect the hull for blisters and stress cracks.

Do a full visual inspection of the entire hull to identify any blisters or cracks. Blisters, if small should be easy to dry out, sanded, filled, and repainted. If they are large, you may want to consider having a professional work on it for you. Cracks are another issue entirely and indicate your boat is stressed and flexing where it shouldn't and cracking the gelcoat. Do not put your boat in the water until you've had a professional inspection/survey performed to identify and resolve the issue.

Outboards, Inboard And Sterndrives

Change the lower unit oil.

If you didn't drain and refill the lower unit oil a the end of the season, do it now. Check the coloration. If it looks like it did when you put it in, that's great! If it looks milky and/or hazy, you most liekly have bad seals and therefore water intrusion. This can completely lock up and destroy your lower unit.

Watch Video: Change the Oil in Your Lower Unit

If you've never replaced your impeller, you are basically just asking to overheat and destroy your entire engine. Most people will replace their impeller every two years, but it really depends on how much use you get out of your boat and whether you flush your engine regularly. Frequent boaters should consider replacing them once a year.

Engine Components

Check belts for tension and wear.

All of the moving components within your engine should be tight. If you have loose belts squealing, that means they are about to give out and leave you stranded. Check for tightness and potential dry rotting.

(Photo: www.boatus.com)

Check steering, power, and trim motor.

Most steering requires some type of lube, and you want to make sure the cables and clamps stay fluid but not too loose. You always want to keep your power trim oil-level topped off as well. Low levels can cause your engine to lose trim capabilities and damage the pumps.

Watch Video: Inspect Steering System

(Photo: www.boatus.com)

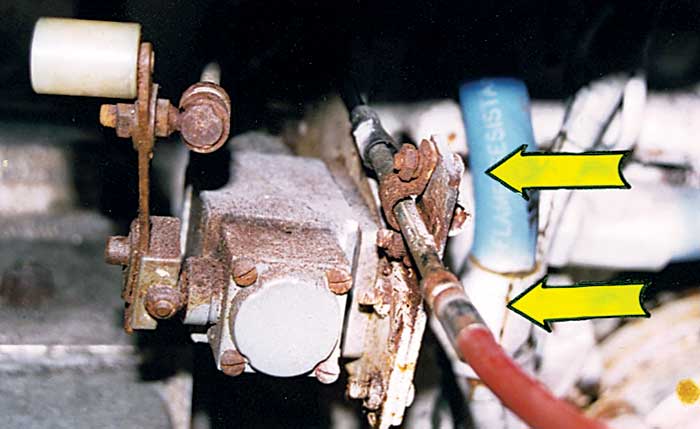

Control cables and linkages.

The clamps and steel cables that control your power need to be inspected. If the tension cables separate from the casing on your power and the whole thing comes loose, it can cause your engine to never make it out of neutral or rev up the rpm's to a deafening level. Cracks or swelling in the jackets or mechanism can indicate corrosion and mean the cable must be replaced. If it fails completely you run the risk of losing complete control of your boat. Squirting WD-40 into the cracks or wrapping duct tape around the outer jackets are not the solution. If it needs to be replaced, it needs to be replaced.

Note: most lubricants are incompatible with what the manufacturers used and will only make things worse.

(Photo: www.boatus.com)

Inspect stuffing boxes.

Loose or leaky engine shafts and rudder stuffing boxes can lead to a sunken boat. When not moving, prop-shaft stuffing boxes should not leak. First try tightening the nut, and if that doesn't work, repack it.

Caution: Over tightening the nut may prevent leaking underway, but it will burn out the packing material and may damage the shaft.

Watch Video: How to Replace a Stuffing Box